Key Takeaway of This Blog

- What is automated inventory management system

- Why you should invest in an automated inventory management system

a. 3 Use cases of an automated inventory management system

b. 3 Benefits of an automated inventory management system - How to choose an automated inventory management system

a. 5 must-have key features of automated inventory management system

Efficient inventory management is a crucial aspect of any business that deals with a huge volume of stock with varieties.

But doing it manually is very slow and erroneous which significantly reduces the productivity of the supply chain.

Together, we explore how wholesalers and distributors can streamline their inventory management processes by taking advantage of an automated inventory management system.

What is automated inventory management system?

What is automated inventory management system?

Effective inventory management serves as the lifeblood of a business.

Today, more and more wholesale distribution businesses realize how important it is to keep inventory management effective.

To cater to this growing demand, various distribution management systems that are comprised of automated inventory management systems are available in Malaysia, each tailored to meet the unique requirements of different businesses nature.

Automated inventory management systems are tools for effectively managing warehouse operations and inventories with minimal human intervention.

Some popular options for wholesale distribution businesses include Sage, Epicor, eCount and Odoo, which masterfully handle inventory management across multiple warehouses.

With one of these automated inventory management systems, you can grab an accurate picture of inventory movements and stock levels, ultimately making stock replenishment decisions more data-driven.

Why You Should Invest In An Automated Inventory Management System?

If you operate a wholesale distribution business in Malaysia, investing in a wholesale management system with automated inventory management is a wise move.

Why?

Below, we listed 3 main use cases and 3 benefits of automated inventory management system.

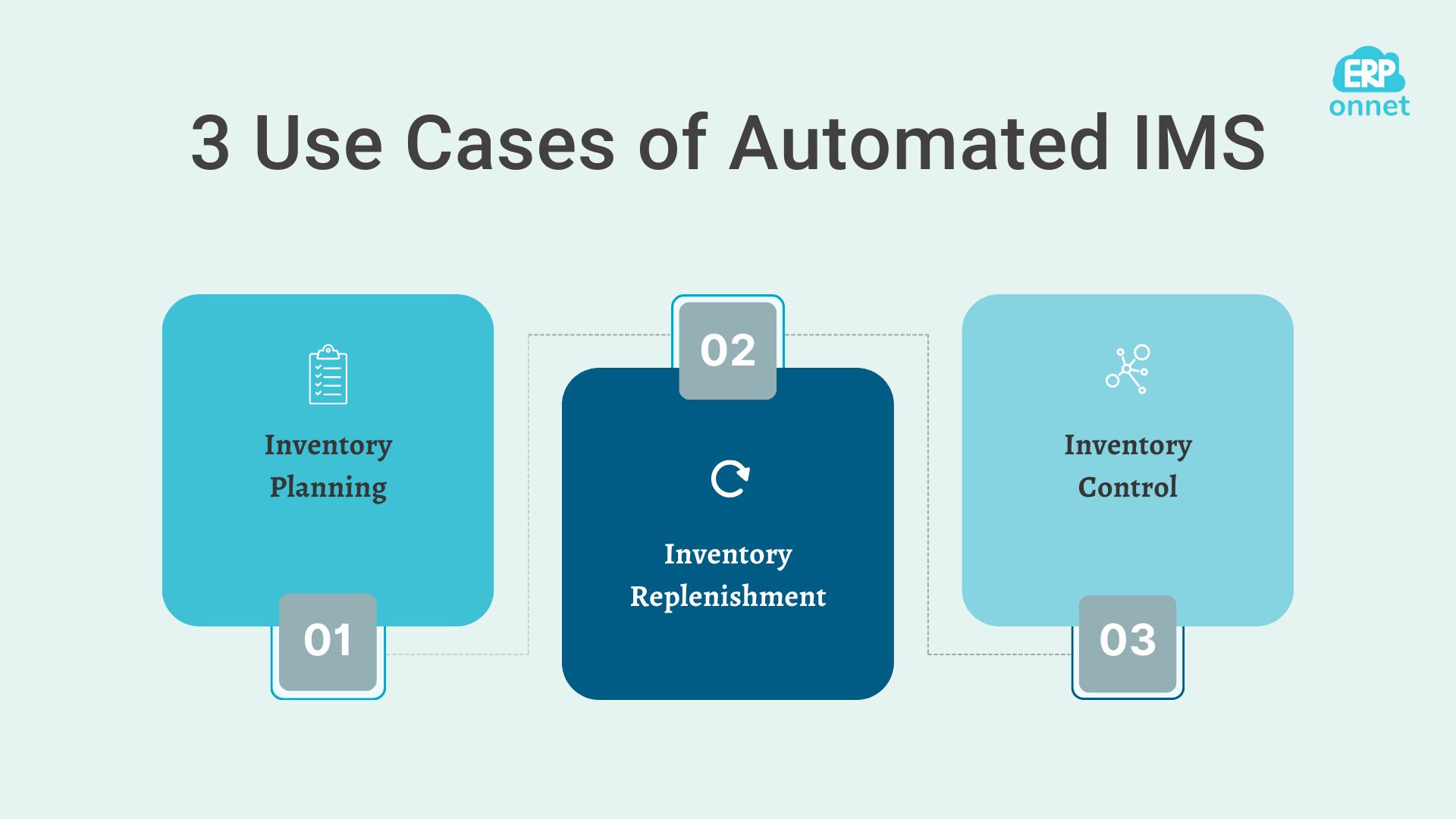

3 Use Cases of Automated Inventory Management System

3 Use Cases of Automated Inventory Management System

Inventory planning

Gain real-time traceability into your inventory movements, allowing you to know when and how much inventory is needed for seamless future sales execution.

Inventory replenishment

Automatically create purchase orders following min-max rules, reducing the risk of frequent out-of-stock and overstock that affect overall business cash flow.

Inventory control

With barcode scanning and lots/serial numbers to track and automatically log the inventory levels, locations, and details, you gain full visibility into your warehouse operations in real time.

3 Main Benefits of Automated Inventory Management System

Save tons of time

Gain full real-time visibility

Increase accuracy

Save tons of time

Thinking of the countless hours your employee spent manually updating inventory data on spreadsheets.

With automated inventory management system, all your stock counts are automatically and accurately updated across all integrated systems.

Each time an item is sold, returned, or received, automated inventory management system records the action and updates the system with barcode scanning without the need for manual intervention.

This automation frees up your time to focus on more valuable tasks.

Gain full real-time visibility

Want to know how much stock you have in your warehouse(s), what is needed for current orders, and what is on the way from your suppliers?

Automated inventory management system helps you to keep track of all of these in real-time.

With real-time visibility of inventory, warehouse managers can easily stay updated on stock levels and make smarter decisions on stock reordering.

Increase accuracy

Counting stock manually is highly prone to human errors.

Automated inventory management system will immediately update inventory data once the items are dispatched, restocked, or moved, thereby reducing any error chances in manual data entry.

Hence, wholesale distribution businesses can depend on the accuracy of the data they receive, reducing the need for manual stock counts, which may only be necessary sometimes to detect potential losses.

How to choose an automated inventory management system?

Based on our more than 9 years experience of serving wholesale distribution businesses in Malaysia, we have summarized the key features that form the core of the automated inventory management system.

5 Must-Have Key Features of Automated Inventory Management System

Serial/lots number tracking

Automated inventory reordering

Automated inventory costing

Multi-warehouse management

Inventory forecasting

Serial/lots number tracking

Serial/lots number tracking

Want to speed up the inventory management process?

Serial/lots number is a must.

Just scan the incoming and outgoing items and the inventory management system will automatically update the stock levels, prioritize older batches, and provide easy traceability.

Automated inventory reordering

Automated inventory reordering

Looking for a way to reduce the risk of stockout and overstock?

Automated inventory reordering comes in handy.

So, you can hold an optimal level of inventory to meet customer needs consistently without excessive storage that costs you a lot.

Automated inventory costing

Automated inventory costing

How to ensure accurate margin calculation?

Automated inventory valuation captures all costs accurately based on FIFO, LIFO, weighted average costing, and other inventory costing methods.

Now, you are able to determine the true COGS, which is essential for profit margin analysis and financial reporting.

Multi-warehouse management

Multi-warehouse management

Facing difficulties in tracking the status of inventory across multiple warehouses in real-time?

Multi-warehouse management within an inventory management system automation provides a centralized platform for overseeing all warehouses from a single location.

This enables quick identification of the warehouse with the needed products, helping you make informed sourcing decisions.

Inventory forecasting

Inventory forecasting

Taking hours on spreadsheets to understand your inventory trends?

You need a dashboard that can show you the parameters you are interested in within seconds!

And, you instantly unlock real-time insights into how your business is performing. You can also make the right adjustments where they truly matter!

Finding the right automated inventory management systems for your business?

Finding the right automated inventory management systems for your business?

After exploring how an automated inventory management system can benefit your business, it is time to find the best one.

Remember to choose a system with the features we talked about.

Odoo is a great option, designed for wholesalers and distributors, offering all those features and more. See why.

And if you are worried that Odoo might not cover all your needs, don't be!

As an Odoo Gold Partner, we have created Odoo Malaysia Localization series specifically for businesses in Malaysia!

We would like to know more about your business model! Talk to us!